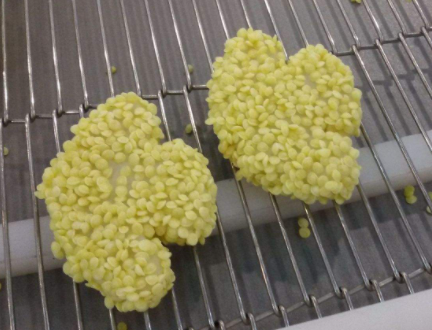

The breadcrumbs coating machine is used in conjunction with the batter wrapping machine and the flour wrapping machine, or it can be used alone. The bran wrapping machine can powder the popular hamburger patties, McNuggets, fish-flavored hamburger patties, potato cakes, pumpkin cakes, meat skewers and other products in the market. It is an ideal powdering equipment for food factories. When the product passes through the conveyor belt, the powder-covered conveyor belt and the powder sprinkled on it are evenly coated with a layer of powder or mixed powder to meet the requirements of the next process. It can be connected with a sizing machine, a breading machine, and a molding machine , Frying machine and other equipment form the production line of different products. Suitable for pre-flouring, flour mixes and fine breadcrumbs. Thereby completing the process of powder, pulp, chips and pulp, powder, pulp, chips.

Features:

The thickness of the upper and lower bread crumb layers is adjustable; powerful fan and vibrator remove excess powder; easy operation and adjustment; special mesh belt crumb spreading technology, uniform and reliable; split screw makes the cleaning process easier; specially designed screw lifts , suitable for different bread crumbs; with reliable safety protection device; the whole machine is easy to clean and meets HA requirements.

Precautions for equipment use:

1. The equipment should be placed on a level ground. For equipment with wheels, the brakes of the casters should be turned on to prevent the equipment from sliding.

2. Connect the power supply according to the rated voltage of the equipment.

3. When operating the bran wrapping machine, do not put your hands into the inside of the equipment.

4. After the equipment is finished working, the power supply must be cut off before the machine can be disassembled and cleaned.

5. The circuit part cannot be washed. When disassembling and washing, be sure to pay attention to other parts that scratch the arm.

Maintenance matters:

1. Every time you clean the equipment and parts that come into contact with food, wipe off the water with a dry cloth before the team leader can get on the machine.

2. Add lubricating oil to the bearings, chains, gears and other transmission parts on the equipment every quarter.

3. The electric control box should be checked regularly to ensure that the circuit is safe and works normally.

Quality assurance:

1. All products of the company can be customized according to customer requirements, and the products are packaged according to wooden boxes, wooden frames, and films.

2. All products are shipped with detailed instructions and some vulnerable accessories.

3. All products of the bran wrapping machine are guaranteed for one year. We have a professional engineering department and maintenance department to provide perfect after-sales service.

Post time: Apr-07-2023