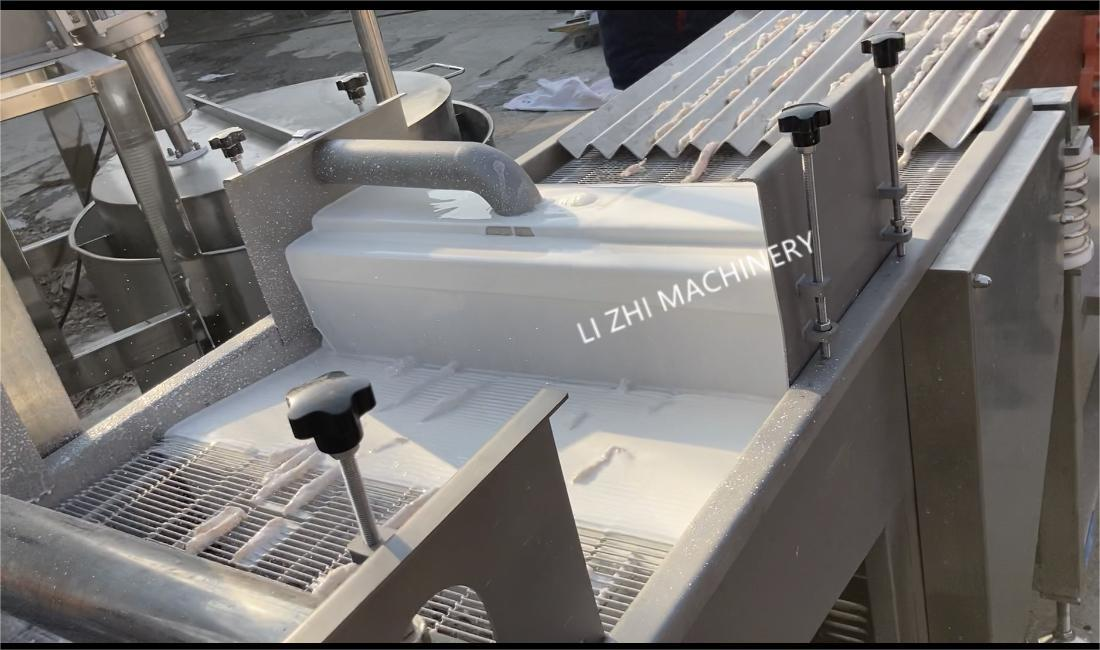

The auto battering machine is used to transport the slurry from the slurry tank to the spraying system through the slurry pump, and then form a waterfall spraying. Products pass horizontally on the conveying mesh belt without disturbing the product row, and the surface and back of the product are sizing at the same time through the circulation pump. The range of processed products of the drench machine: snack food, chicken, beef, pork, fish, shrimp and other seafood products.

Compared with manual batering, the battering machine not only sizing quickly and evenly, but also can control the amount of batteirng according to the product processing requirements, and blow off the excess sizing through the air knife. The sizing machine is used for sizing, and the products are conveyed by the mesh belt, which not only arranges neatly, sizing is uniform, and has high output, but also can be used in conjunction with other equipment to achieve continuous production. The slurry can be recycled to avoid waste. At the same time, the ice storage tanks on both sides of the slurry machine can be filled with crushed ice water to maintain low temperature sizing, effectively ensuring the quality of the slurry and product quality.

Operation points of the pouring machine:

1. Place the battering machine at a suitable working place and connect the power supply according to the rated voltage;

2. Inject the prepared slurry into the slurry tank, there is a slurry filter cover in the slurry tank, the depth of the slurry must not be without the filter cover;

3. Start-up sequence: start the conveying mesh belt, start the slurry pump, adjust the flow rate of the slurry inlet valve, so that the slurry spraying system forms a uniform waterfall, covering the entire width of the mesh belt, and then put the product into it for sizing;

4. During the sizing process, according to the sizing situation, properly adjust the conveying speed of the mesh belt and the position of the air knife, so that the products are neatly arranged and fully coated;

5. Shutdown sequence: fan stop, slurry pump stop, mesh belt stop;

6. The slurry pump of the slurry sprayer is strictly forbidden to run without load.

Post time: Mar-31-2023